- [email protected]

- +92-333-9114765

- You can conatact us any way that is convenient for you

Well drilling is the engineering of exploringand utilizing water resources in strata by using water well drill bits and technology. Groundwater is water that exists in cracks of the earth's crust or in gaps in the soil. The various states of water buried below the surface are collectively referred to as groundwater.

Clean Sand and Gravel Sedimentary Rock

Clean sand and gravel sedimentary rock is the best source of water. This kind of structure has strong water absorption, high water content and good water permeability

The Mixed Layer of Sand and Gravel

The sand and gravel mixture is also a water-yielding structure. Because of the different proportions of sand, it is a secondary water-producing rock. The lower the sand content, the higher the water yield.

Clay Structure

Although the clay structure holds water well, it is difficult for water to move through it. This means that the clay structure does not flood the well, so it is not an aquifer.

The Sandstone

It refers to the terrigenous clastic rocks whose grain size is 0.0625 ~2 mm and the sand accounts for more than 50% of all clastic particles. If the clay acts as a cement in sandstone to hold the sand together, then it is a poor water-yielding rock.

Limestone

It is an excellent source of water in all sedimentary rocks. Limestone usually has large openings, such as underground karst caves that contain high water content but poor water quality.

Basalt

In the earlier time, its beds are dense rather, so it is rather than a good water-yielding because they are tightly packed together. If it’s in later time,and it has spongy development, then it’s a good source of water.

Hard rock

Such rocks as granite, porphyry, and other crystalline rocks are usually poor water producers. The worst water-yielding are metamorphic rocks such as gneiss schist, quartzite, SLATE, and soapstone.

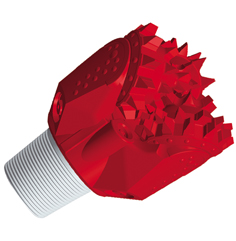

In order to avoid the low efficiency of well drilling, the oil standard Tricone bit specification should be adopted in the design of the well drilling diameter. The selection of leading hole standard cone bit must be beneficial to the processing of reaming assembly cone bit in order to reduce the processing cost of bit. The effect of drilling parameters on drilling efficiency is weight on bit.

Great is dedicated to the design, production, and sales of diverse water well drill bits. The produced models of our water well drill bits for sale are (76mm-660mm) Mill tooth bit and TCI bits. Customers can also customize and assemble their own well drilling bits according to their actual needs.

Great’s water well drill bits are available in both composite seals and metal seals, so as to better meet the requirements of different engineering projects. The number of tooth rows, the number of teeth, the height of the teeth, and the alloy tooth profile are also well-designed to provide a better cutting ability for the drilling bit and improve the service life simultane. Available IADC Code of our water well drill bits for sale include 437,517,537,617,637etc.

The price of Great water well drilling bits approximately start from $1000 on the basis of different sizes and types. You are more than welcomed to send your detailed inquiry to us,so that we can offer you the best price for our long term cooperation.

The weight of the water well drill bits should be determined according to the formation’s hardness and softness. Meanwhile, the quality of water well bit, well bore, drilling tool, displacement, and performance of flushing fluid, equipment and power should also be considered.

When choosing the tricone water well bits, you should select tricone rock bits to suit lithology requirements as much as possible, match bit size with drilling design, and use in order of size. In the process of using the water well drill bits, if the phenomenon of rampage occurs, the reasons should be analyzed immediately to check whether the formation changes or the borehole wall collapses. The parameters should also be analyzed and adjusted immediately. If the up-lift bit can’t be drilled normally, the up-lift bit should be checked.

The regular analysis of the working conditions of the water well drill bits in the hole is also important for the maintenance of the drill bit. In addition, measures should be taken to control well deviation, reduce the clearance between drilling tools and drilling holes, and play the role of full hole drilling and rigid anti-deviation.

In order to prevent deviation, centralizer and drill collar can be added on the top of the tricone bit.

GREAT can recommend the right water drill bit type according to your drilling demand.

Steel tooth drills are suitable for extremely soft formations with low compressive strength and high drillability such as clay, mudstone, chalk, etc..

Overview 120 ° U-shaped Roller bitGREAT has customized manufacture several types of roller bit . The traditional roller bit was cut by tricone bit . So it is including No.

Tricone bit is an important tool for oil drilling.

Oct 10,2023

Paving the Way: Hole Opener Drill Bits in Municipal Construction and Development

Sep 05,2023

Digging Deeper: The Evolution of Tricone Drill Bit Design in Mining Applications

Dec 15,2020

Selection of Reamer during Construction