- [email protected]

- +92-333-9114765

- You can conatact us any way that is convenient for you

Geothermal drilling characteristics of geothermal drilling the main oil and gas well drilling technology for reference, because the heat reservoir rock geological conditions, such as lithology, buried depth and output fluid property is different, compared with more demanding conditions of oil and gas drilling, geothermal drilling, but also for geothermal well characteristic of the high temperature and large diameter to new technology and new equipment improvement and development.

Compared with oil and gas drilling, geothermal drilling has the following characteristics:

High temperature, great variation in buried depth.

The rock is hard, abrasive and high in-situ stress heat storage rocks are mostly volcanic and metamorphic rocks. Compared with the deposition rock of oil and gas wells, the rock is hard, abrasive and high in-situ stress, and the stratum is broken and often unstable.

The crack height is developed, and even centimeter-grade cracks exist.

Formation pressure is low and leakage is serious.

The formation often contains corrosive fluid, which is corrosive to drilling string, casing, etc.

This requires the production of expensive titanium alloy bushing and the development of special cement.

The geothermal well has a large diameter, many casing procedures and a large amount of cement.

Drilling a geothermal well is similar to drilling oil, gas and well. In order to overcome the special difficulties in drilling, drilling methods, flushing media, drilling tools, casing head structure, wellhead device and other appropriate technical measures should be adopted.

The drill pipe and drill collar with high-temperature resistance, corrosion resistance, low coefficient of thermal expansion and high strength should be used in the drill pipe and drill collar.

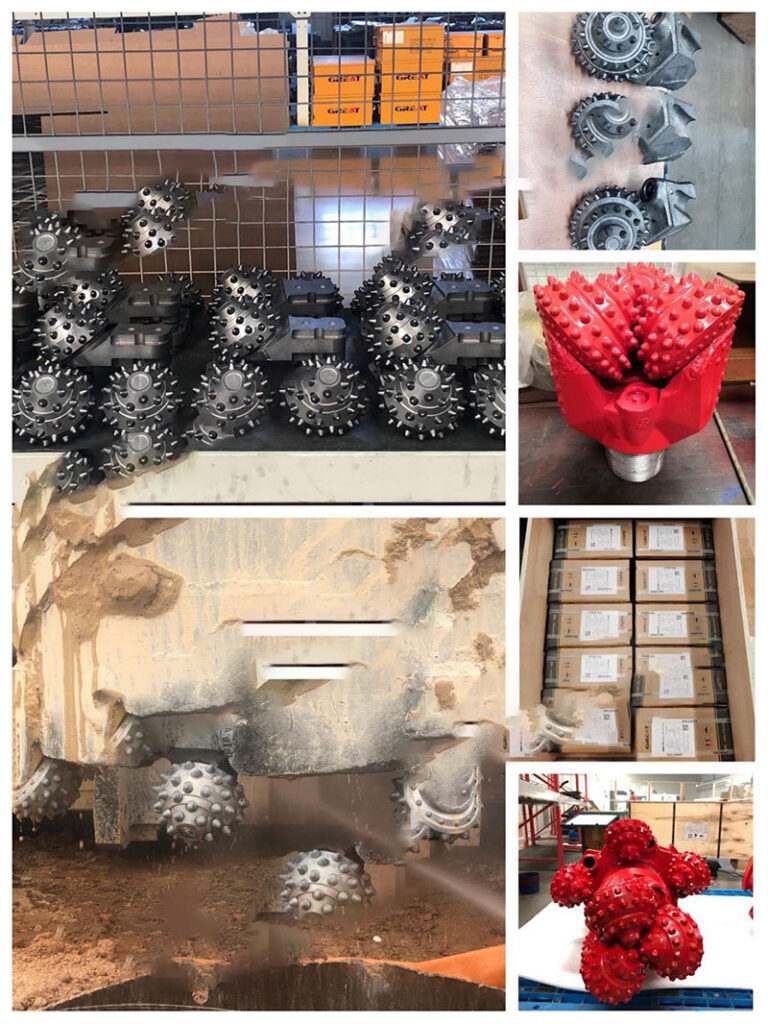

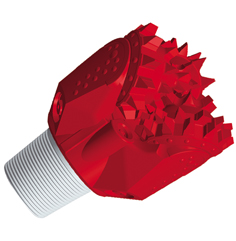

And we will recommend high-quality PDC bit and Tricone bit of GREAT.

Steel body PDC bit is made by AISI 4145H heat treatment steel manufacture, it has lower cost compare with Matrix body PDC bit.

Steel tooth drills are suitable for extremely soft formations with low compressive strength and high drillability such as clay, mudstone, chalk, etc..

Matrix body PDC bit is made by Tungsten carbide podwer , it is very high hardness material , mainly used for deep Oil&Gas well drilling.

Oct 10,2023

Paving the Way: Hole Opener Drill Bits in Municipal Construction and Development

Sep 05,2023

Digging Deeper: The Evolution of Tricone Drill Bit Design in Mining Applications

Dec 15,2020

Selection of Reamer during Construction