- [email protected]

- +92-333-9114765

- You can conatact us any way that is convenient for you

Steel body PDC bit is made by AISI 4145H heat treatment steel manufacture, it has lower cost compare with Matrix body PDC bit.

Steel body PDC bit is made by AISI 4145H heat treatment steel manufacture, it has lower cost compare with Matrix body PDC bit.

Steel body PDC bit is made by AISI 4145H heat treatment steel manufacture, it has lower cost compare with Matrix body PDC bit.

Steel body PDC bit is made by AISI 4145H heat treatment steel manufacture, it has lower cost compare with Matrix body PDC bit.

Steel body PDC bit is made by AISI 4145H heat treatment steel manufacture, it has lower cost compare with Matrix body PDC bit.

What is PDC material? According to the production material, the PDC drill bits for sale on the current market can be roughly divided into the following two types:

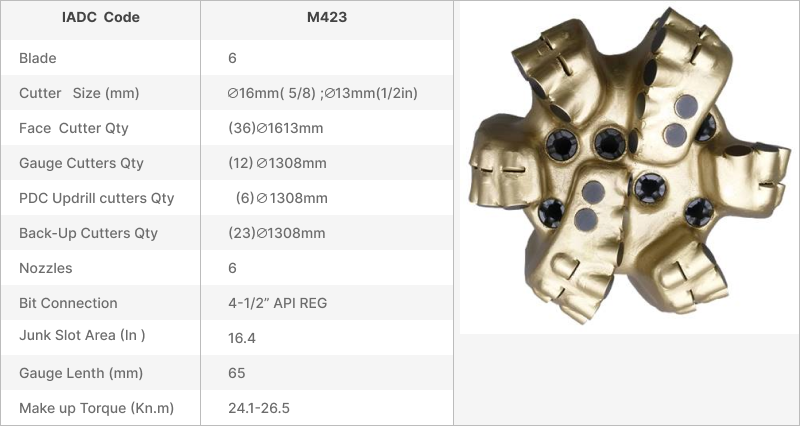

Matrix body PDC bit: This type of diamond PDC bit is made of tungsten carbide powder, and the gauge protection is TSP.

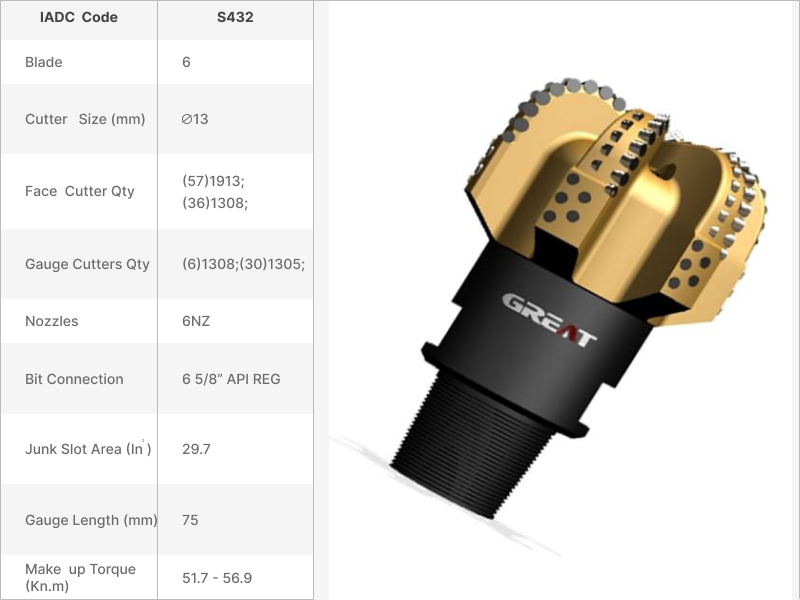

Steel body PDC bit: With the AISI 4145H heat treatment steel (America standard steel ), the steel body PDC bit can be used for high-quality CNC machines milling pockets, blade, nozzles.

Most of the raw material Great uses for our diamond PDC bit is made in USA and France. Our supplier technical engineers will come to our factory to train our welder and have meetings with us so as to show their new products regularly. We communicate with our suppliers very well. So if our customers need it, we, as PDC drill bits manufacturers, can ask our engineers to have a meeting with each other face to face.

Mining Industry

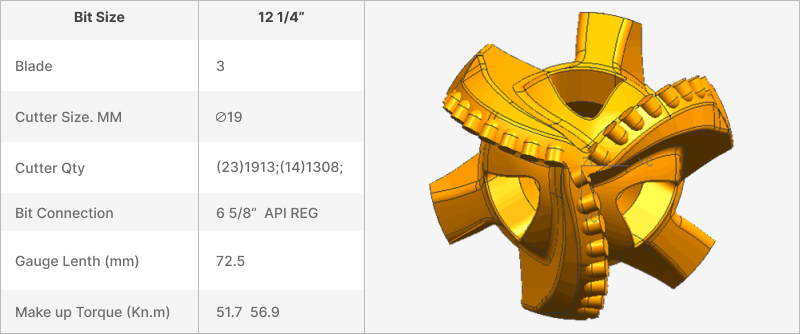

There are some 3-blade PDC bits mainly used for the mining industry in Australia, and Russia. The formation is very soft. Choosing a Steel body PDC bit can save more drilling costs.

Water well drilling

Having higher ROP, diamond PDC drill bits are also widely used as water well drill bits for geothermal drilling.

Oil & Gas drilling

– Polycrystalline diamond compact bit is the most widely used bit in the field of Oil &Gas drilling. Hydraulic factors are very important to the bit during drilling.

– PDC bits have been used in areas that were previously unavailable, such as harder, more abrasive, and more variable formations.

– This expansion into the new field has a great impact on the balance between the diamond (fixed cutter bit) bit and Tricone rock bit.

– The diamond PDC bit is mainly composed of the bit body, cutting teeth, nozzles, gauge protection, and API Thread connection.

If your drilling has any problem, GREAT can provide a solution and service.

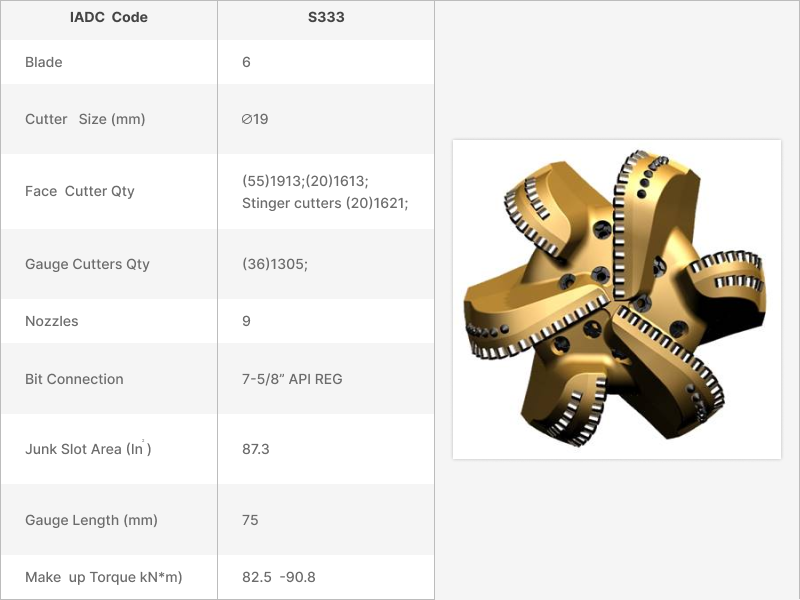

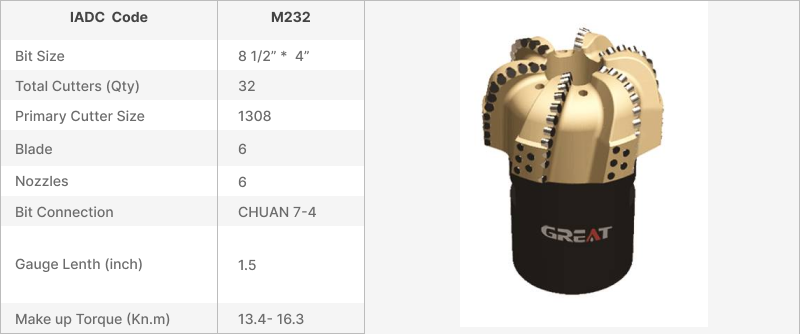

There are several key specifications to consider when selecting a PDC drill bit. These include: Blade, Cutter Size and so on.

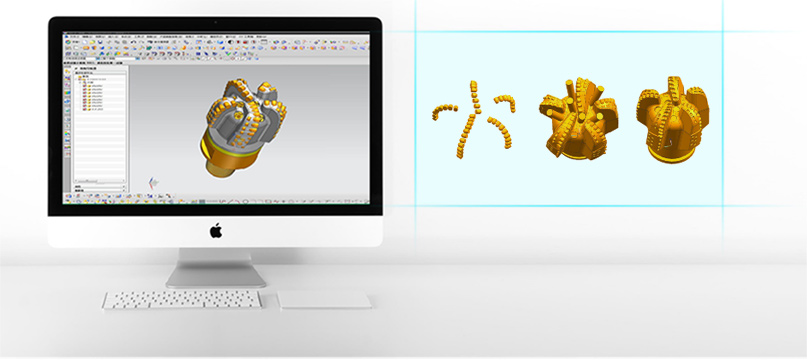

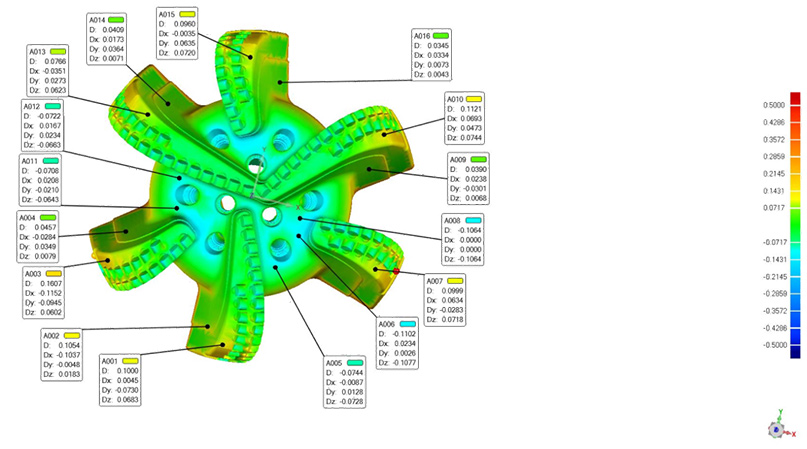

The advanced designing software of GREAT is the guarantee of precision and reliability of the development. Our continuous improvement for a specific application results in continuously outperforming PDC drill bits for sale than the previous ones.

How much does a PDC drill bit cost? You may be interested in this. While PDC drill bits price varies from different materials and types. To increase the efficiency and quality of use, the PDC drill bit cost is an important part of the equipment, which is why you cannot compromise on their quality. All the pdc drill bits for sale are subjected to strict quality control by GREAT to ensure that you always receive maximum satisfaction. Contact us to get the quote for your customized PDC drill bits.

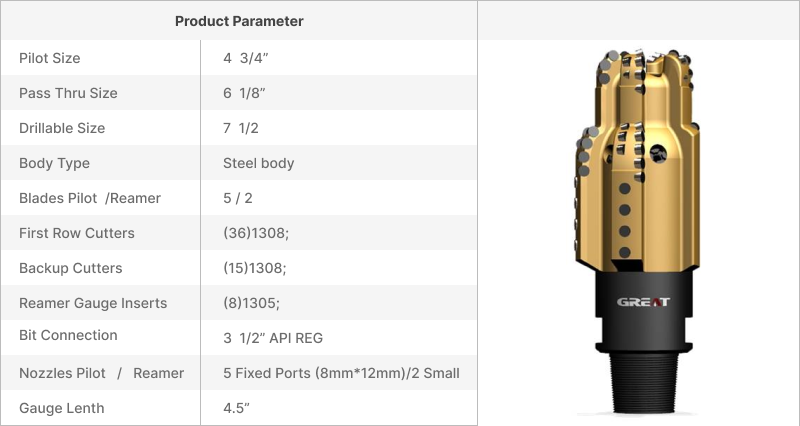

Horizontal directional drilling technology is a new construction technology that combines the directional drilling technology of

Customized bigger diameter Hole openers for tunneling, such as subway, gas pipeline.