- [email protected]

- +92-333-9114765

- You can conatact us any way that is convenient for you

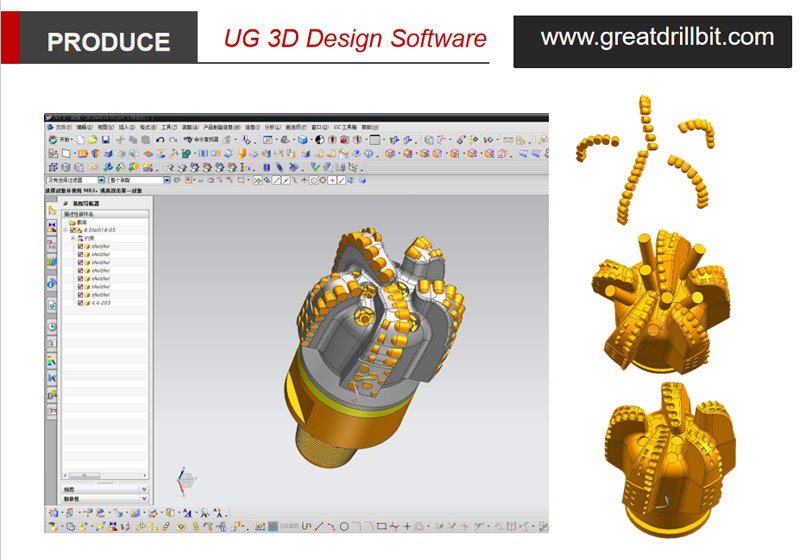

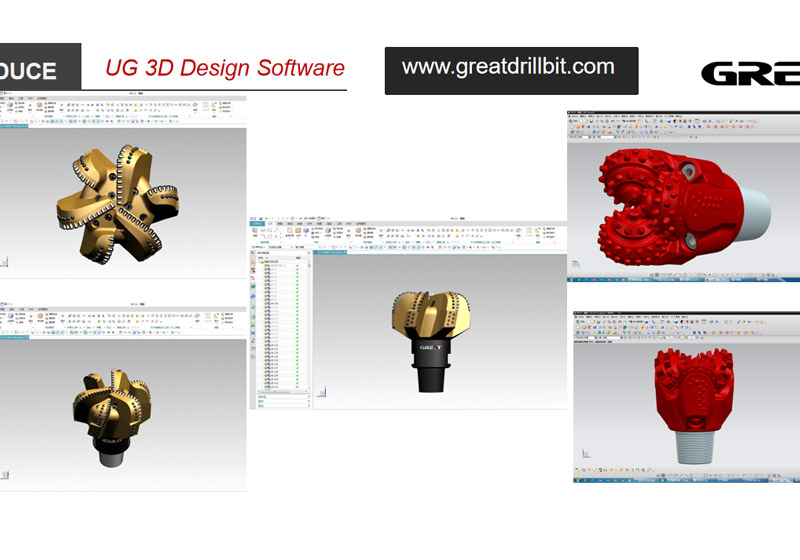

The advanced designing software is the guarantee of precision and reliability of the development.

The continuous improvement for a specific application results in continuously outperforming bits than previous designs.

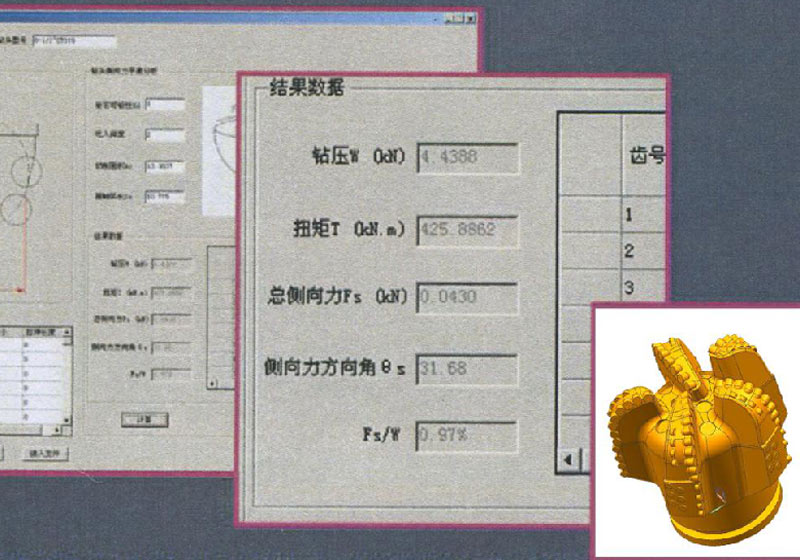

With the help of force balance analysis, we can adjust the cutter configuration and distribution, decrease the unbalance force, mitigate the whirling on bottom and protect the PDC cutters to extend the bit’s life.

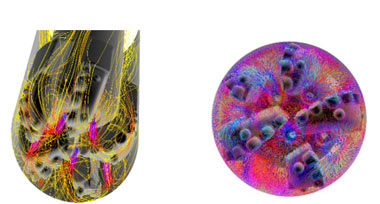

Optimized hydraulic design; CFD fluid dynamic analysis software

By means of the advanced fluid dynamic analysis software, simulate the down hole bit the drilling fluid interaction, to optimize the bit cleaning the cutters cooling.

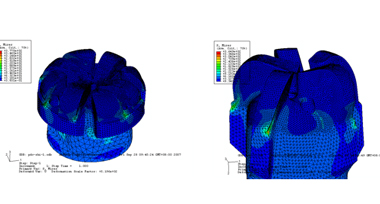

The 3-D finite element analysis model can help to simulate the downhole bit and rock interaction, and to analyze the mechanical state of the bit body and PDC cutters, thereby optimizing bit body and PDC location, and ensuring safe and efficient drilling

Three dimensions finite element analysis